Satake design and build feed milling plants for poultry, livestock and aquaculture feed production.

Plants can be designed to produce pelleted or mash feed and include all the equipment necessary for a ‘turnkey’ solution.

Many of Australia and New Zealand’s largest feed mills have been built by Satake.

We also offer complete plants for wood pelleting and the processing and pelleting of other organic materials.

Satake are Australia’s feed mill engineering and construction experts.

Complete plant engineering is Satake’s domain. Whether it be for livestock feeds, poultry or aquaculture, Satake has the technology and engineering support to build your solution.

Satake know that the correct storage and handling of raw materials is vital in any successful feed milling operation.

We provide solutions for product receiving, transfer and storage.

Our intake systems are designed to quickly and safely unload the incoming vehicle, transfer the product to the storage system and then accurately discharge to the onward process.

We can provide weighing systems, pre-cleaners and stock level control systems within the intake and storage package.

Satake’s high capacity cleaning equipment ensures that the feed produced is consistent, hygienic and to the best possible quality standards.

Satake provide equipment for separation by:

– Size

– Shape

– Specific gravity

– Air resistance

– Special peculiarity (e.g. magnetic)

Satake ‘G’ Series Hammer Mills

Satake Australia manufacture high quality, energy efficient hammer mills for the coarse grinding of poultry and livestock feeds and the fine grinding of meals for aqua feed.

Our hammer mills are used in a variety of industries for grinding organics and minerals.

Our Sydney offices have facilities for test grinding products to determine performance and capacities of client provided samples.(more)

CPM Roskamp Champion Hammer Mills

Through our agreement with CPM Roskamp Champion USA, Satake Australia supply the complete range of Champion Hammer Mill products.

Champion hammer mills are designed for the most demanding operations. These rugged, high-efficiency hammer mills are capable of fine-grinding either friable or fibrous materials. For over 50 years, Champion has produced high-quality hammer mills for feed, oilseed and industrial processors. (more)

Through our representative agreement with CPM Roskamp Champion USA, Satake Australia supply the complete range of Roskmap Roller Mill products.

Roskamp roller mills are the ideal machine for a wide variety of grinding applications. Equipped with solid rolls for long life and reliability, Roskamp roller mills offer up to 60% energy savings when compared to a typical hammermill system. (more)

The Satake FHRA Batch Mixer is designed to mix all free flowing dry solids encountered in the stock feed, pet food, flour milling, food and chemical industries.

The Batch Mixer will accurately homogenise macro and micro ingredients in a rapid cycle time and when fitted with special features will also blend in small volumes of liquid.

Satake have constructed some of the largest pelleting plants in Australia and New Zealand.

Pelleting reduces the volume of bulk products and make transport, storage and end-use easier to manage. It can also improve the enzyme activity and compared to mash feed, pellet feed can increase the feed conversion rate by 10% to 20%.

Satake pelleting system can be used in many industries and for many products. The products that we handle include cereals, pulses, spent grains, wood and other organic materials.

We also hold a compressive inventory of pellet press dies in stock for immediate delivery.

Through our agreement with CPM Roskamp Champion USA, Satake Australia supply the complete range of California Pellet Mill products.

CPM pellet mills are meticulously engineered and highly efficient. They are built for around- the-clock production and driven by up to 800 horsepower. The mills are ideal for producing pellets for full line feeds, wood, single ingredients, coal, poultry feed, hog feed, paper, corn wet milling or any of the thousands of products our customers pellet. (more)

Through our representative agreement with CPM Roskamp Champion USA, Satake Australia supply the complete range of Roskamp Champion Flaking Mill products.

A flaking mill is used to compress and flatten a product into a thin and uniform product. The flaking process is very important in achieving the maximum nutritional potential of a feed pellet. (more)

Flaking mills are commonly used in oil seed applications to prepare materials for mechanical or solvent extraction. Flaking increases the surface area of the material and reduces the distance the oil or solvent must travel. For certain high oil materials, flaking also ruptures some of the oil “cells” releasing the oil for easier extraction. Materials commonly flaked for oil extraction include soybeans, Canola/rape seed, sunflower and safflower seed, cotton seed, corn germ, palm kernel, and copra (coconut)

In animal feeding, steam flaked grains are used to improve feed efficiency and increase meat and milk production. Whole grains (corn, barley, wheat, rye) are conditioned with live steam to increase the temperature and moisture level, then flaked between large diameter rolls. Flaking increases the surface area of the grain, and causes a percentage of the starch to be gelatinized. Both the feed form and increased levels of starch gelatinization improve the bio-availability of the energy and nutrients available in the grain.

The Satake Pellet Crumbler is used to reduce pellets produced on a press to “crumbles”. The pellets are ground between two fluted rolls that are fully adjustable allowing accurate particle size reduction.

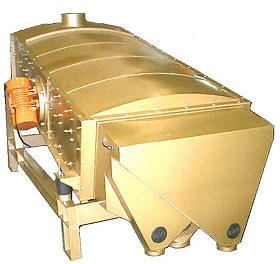

The Prater/Satake Pellet Sieve has evolved from over 70 years experience of the Prater Industries Incorporated Group of Companies in Chicago, USA.

Satake Australia manufactures this well proven unit under licence to Prater Industries.

The sieve is also capable of duties other than pellet screening where scalping and sizing of coarse and fine particles are required.

Satake can engineer and supply bulk out loading systems for pellets, flakes, mashes and flours.

Our design can include dust control systems, weighing, product traceability systems and vehicle movement controls.